DTF Custom Apparel disrupts traditional garment production with direct-to-garment technology, offering faster, cost-effective creation of small batches or single items featuring intricate designs. This method eliminates inefficiencies and waste associated with conventional methods, providing vibrant, high-quality prints with a soft hand feel while ensuring customer satisfaction.

“In the realm of custom apparel, DTF (Direct to Fabric) printing has emerged as a game-changer, revolutionizing the way we create personalized garments. This innovative method compares favourably—and in many cases surpasses—traditional techniques. Traditional methods are often time-consuming and limiting, but DTF offers unprecedented efficiency, superior quality, and enhanced customer satisfaction. Discover how this modern approach is transforming the industry, allowing for intricate designs without the usual constraints.”

- Understanding DTF Custom Apparel: A Modern Approach

- Traditional Methods: Limitations and Time-Consuming Processes

- Advantages of DTF: Efficiency, Quality, and Customer Satisfaction

Understanding DTF Custom Apparel: A Modern Approach

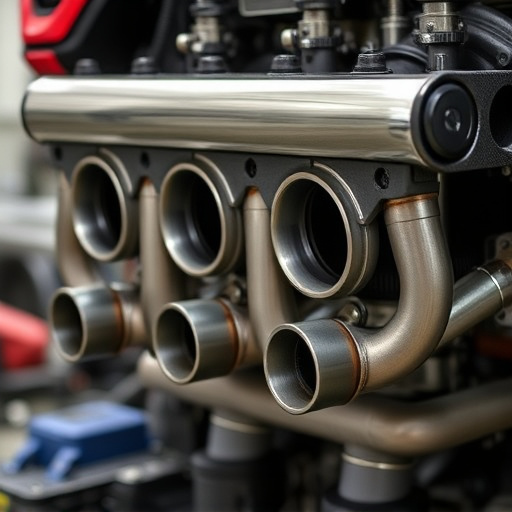

DTF Custom Apparel represents a modern approach to garment decoration, offering a streamlined and efficient method for creating personalized clothing. This innovative technique, short for Direct-to-Garment (DTF), has disrupted the traditional methods of printing on fabrics. Instead of using custom sheets for heat pressing designs onto garments, DTF directly applies ink to the garment’s surface, ensuring precise and vibrant graphics.

With DTF for Custom graphic tees, the process is both faster and more versatile. It eliminates the need for complex setup and long production times commonly associated with traditional methods. This makes it an attractive option for businesses and individuals looking to produce small batches or even single items with intricate designs quickly and cost-effectively.

Traditional Methods: Limitations and Time-Consuming Processes

Traditional methods of garment production, while proven and reliable, come with significant limitations that can make them inefficient and time-consuming. The process typically involves multiple stages, from design creation to cutting, stitching, and finally, packaging. Each step relies on specialized equipment and skilled labor, which can lead to longer turnaround times and higher production costs.

For instance, creating custom designs often requires intricate handwork or the use of specific software, followed by printing on fabric sheets before transferring them onto garments via heat pressing or other techniques. These methods not only demand precision but also leave room for human error, impacting overall quality. In contrast, DTF Custom Apparel offers a streamlined approach, directly applying personalized designs to fabrics and garments with advanced technology, ensuring faster production times and superior accuracy.

Advantages of DTF: Efficiency, Quality, and Customer Satisfaction

The Direct-to-Garment (DTF) method of custom apparel printing offers several advantages over traditional techniques. One of its key strengths lies in efficiency; DTF allows for faster production times and reduces waste, making it an eco-friendly option. This process involves applying heat-transfer paper directly onto garments, enabling intricate and detailed designs with precision. As a result, businesses can cater to small batch orders or even custom single pieces without the usual delays associated with bulk printing.

In terms of quality, DTF custom apparel sets a new standard. The advanced printing technologies ensure vibrant, long-lasting colors that remain consistent across various garment types. This method also allows for a wider range of design possibilities, including full-color images and complex graphics, which can be achieved without the need for specialized equipment or screens. Customer satisfaction is another significant benefit, as DTF prints offer a soft hand feel and ensure the design seamlessly integrates with the fabric, providing a high-quality, professional finish.

DTF (Direct to Fabric) Custom Apparel has emerged as a game-changer in the apparel industry, offering a modern alternative to traditional methods. By streamlining the design and production process, DTF provides unparalleled efficiency without compromising quality or customer satisfaction. This innovative approach allows for faster turnaround times, precise color reproduction, and unique customization options, making it an attractive choice for both businesses and individuals seeking cutting-edge clothing solutions. Embrace the future of fashion with DTF Custom Apparel and experience the benefits firsthand.