DTF Custom Apparel is a revolutionary printing method for creating unique, high-quality clothing. By directly applying inks to fabrics like cotton, polyester blends, designers achieve vibrant, durable prints on hoodies and t-shirts. Fabric choice and precise heat press settings are key for successful DTF transfers, ensuring long-lasting custom apparel.

“Unleash your creativity with Direct to Fabric (DTF) printing for custom apparel projects. This innovative technique allows for vibrant, long-lasting designs on a variety of fabrics. In this guide, we’ll explore the ins and outs of DTF printing, from understanding the process to selecting the best fabrics. Discover top choices tailored for optimal print quality and durability, and learn how various factors impact your DTF apparel’s final look and longevity. Elevate your custom clothing creations with these insights.”

- Understanding Direct to Fabric (DTF) Printing

- Top Choices for DTF Printable Fabrics

- Factors Influencing DTF Apparel Quality & Durability

Understanding Direct to Fabric (DTF) Printing

Direct to Fabric (DTF) Printing is a cutting-edge technique that has revolutionized the world of custom apparel. Unlike traditional methods that rely on printing onto paper and then transferring the design, DTF technology allows for precise application of inks directly onto various fabrics. This innovative process enables detailed and vibrant prints, making it an excellent choice for DTF Custom Apparel projects.

By skipping the transfer stage, designers and clothing brands can achieve exceptional results with DTF printing for hoodies and other garments. The method ensures that logos and designs become an integral part of the fabric, resulting in long-lasting, high-quality prints. Understanding this process empowers creators to bring their artistic visions to life on a range of fabrics, from cotton tees to polyester jackets, offering endless possibilities for unique DTF custom apparel.

Top Choices for DTF Printable Fabrics

When it comes to DTF custom apparel projects, choosing the right fabric is key to achieving high-quality and durable results. Top choices for DTF printable fabrics include cotton, polyester, and blends of both. Cotton is a popular option due to its soft texture and ability to absorb ink effectively, making it ideal for creating vibrant designs on t-shirts, hoodies, and more. Polyester fabrics are also favored for their durability, quick-drying properties, and resistance to fading, which makes them suitable for activewear and sports apparel.

Blends of cotton and polyester offer the best of both worlds—combining the comfort of cotton with the durability of polyester. These fabrics are versatile and can be used for a wide range of DTF printing projects, from casual wear to specialized gear. Understanding the properties of different fabrics will help ensure that your DTF transfer process is successful, resulting in long-lasting and visually appealing DTF custom apparel.

Factors Influencing DTF Apparel Quality & Durability

The quality and durability of DTF (Direct to Fabric) custom apparel projects are significantly influenced by several factors. One of the primary considerations is the fabric chosen for printing. Different fabrics have varying levels of absorbency, texture, and elasticity, all of which play a crucial role in how well heat-transfer designs adhere and wear over time. For instance, 100% cotton or poly-cotton blends are popular choices due to their softness, breathability, and ease of printing.

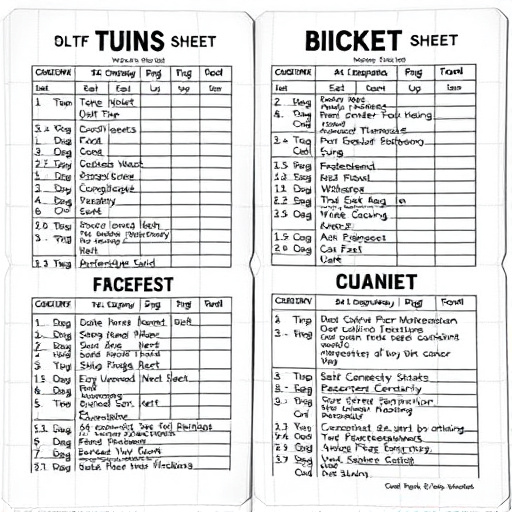

Additionally, the heat press process itself is a critical aspect. Using custom sheets designed for heat pressing ensures optimal transfer of designs onto garments. The temperature, pressure, and duration applied during heat pressing must be carefully balanced; too much or too little can result in poor design quality or faded prints on custom t shirts and other apparel items. Proper preparation of the fabric surface and selection of appropriate heat press settings are essential to achieve long-lasting, vibrant designs on DTF custom apparel projects.

When it comes to creating high-quality and durable DTF custom apparel, selecting the right fabric is key. By understanding the principles of Direct to Fabric (DTF) printing and choosing from the top printable options available, you can ensure your designs last and look their best. Consider factors like material composition, weight, and texture to optimize print quality and end result. With the right fabric choice, your DTF custom apparel projects will truly stand out in the market.