DTF Custom Apparel leverages a cutting-edge printing technique applying direct designs onto various fabrics for vibrant, durable results. Versatility and speed make it popular for high-quality personalized garments. Choosing the right fabric – like cotton or poly-cotton blends – is crucial for exceptional print quality, with considerations for breathability, texture, and colorfastness. This method seamlessly integrates intricate designs into fabrics like hoodies, perfect for unique apparel.

Discover the best fabrics for your DTF (Direct-to-Fabric) custom apparel projects. This guide delves into the world of DTF printing, focusing on suitable fabrics for exceptional print quality. From understanding fabric types to considering key factors, you’ll learn how to choose materials that enhance your designs and meet project requirements. Elevate your DTF custom apparel with these expert recommendations.

- Understanding DTF Custom Apparel and Suitable Fabrics

- Top Fabric Choices for Exceptional Print Quality

- Factors to Consider When Selecting Fabrics for DTF Projects

Understanding DTF Custom Apparel and Suitable Fabrics

Understanding DTF Custom Apparel involves embracing a cutting-edge printing technique that revolutionizes the way we create personalized garments. DTF stands for Direct to Fabric, offering a direct application of design onto various fabric types, resulting in vibrant and durable prints. This method has gained immense popularity among designers and entrepreneurs due to its versatility and ability to produce high-quality custom apparel quickly.

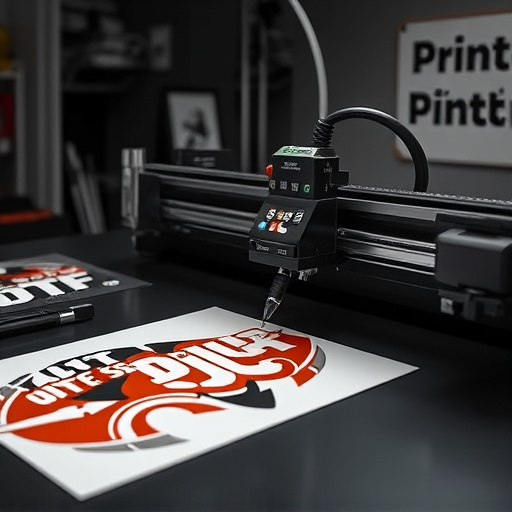

When selecting fabrics for DTF Custom Apparel projects, it’s crucial to consider the material’s characteristics, such as breathability, texture, and colorfastness. Natural fibers like cotton and linen are excellent choices for their comfort and ease of printing. On the other hand, synthetic blends can provide a smoother finish and better ink adhesion. For t-shirts, a 50/50 blend of cotton and polyester is commonly used due to its balance between comfort and durability. Custom DTF transfers, applied using specialized transfer film, ensure that intricate designs and vibrant colors are seamlessly integrated into the fabric, making it an ideal solution for creating unique, personalized garments.

Top Fabric Choices for Exceptional Print Quality

When it comes to achieving exceptional print quality in DTF custom apparel projects, the fabric choice plays a pivotal role. For the best results, opt for fabrics that offer a smooth surface and good absorbency. Cotton and poly-cotton blends are popular favorites due to their versatility and ability to seamlessly accommodate dtf transfers. These fabrics provide a superior printing canvas, ensuring crisp and vivid designs.

Additionally, looking into performance fabrics like polyester or nylon can be advantageous for specific applications. These materials offer enhanced durability and fast-drying properties, making them ideal for activewear or outdoor apparel. Incorporating high-quality fabrics and precise dtf transfer film application will undoubtedly result in visually stunning DTF printing for hoodies and other custom apparel items.

Factors to Consider When Selecting Fabrics for DTF Projects

When selecting fabrics for DTF (Direct to Fabric) custom apparel projects, several key factors come into play. Firstly, consider the type of garment and its intended use. Different fabrics offer unique characteristics like breathability, stretch, or durability, each suited to specific activities or weather conditions. For instance, lightweight cotton t-shirts are ideal for casual wear, while polyester blends excel in athletic apparel due to their quick-drying properties.

Secondly, the fabric’s compatibility with DTF printing methods is essential. Not all materials adhere to heat presses equally well. Smooth, flat surfaces like 100% cotton or poly-cotton blends facilitate even heat transfer, resulting in crisp, vibrant DTF designs on t-shirts and other items. Additionally, fabric weight plays a role; lighter fabrics allow for more detailed printing while heavier ones may require specialized techniques to prevent ink saturation.

When embarking on DTF Custom Apparel projects, fabric selection is key. By understanding the unique requirements of direct-to-fabric (DTF) printing and choosing appropriate materials like polyester blends, cotton-polyester mixes, or performance fabrics, you can achieve exceptional print quality and durable, high-quality garments. Remember that factors like breathability, texture, and ink compatibility play a crucial role in the final outcome, so carefully consider these aspects to create vibrant, lasting designs that cater to your target audience’s needs.